Contact Info

Add:Tangyan Mansion, No. 58 Keji 1st Road, High tech Zone, Xi'an City, Shaanxi Province, P. R. of China.

Phone: 0086-29-84504928

E-mail: Tisales@omdtimetal.com

Product Search

Quickly Find The Product You Need

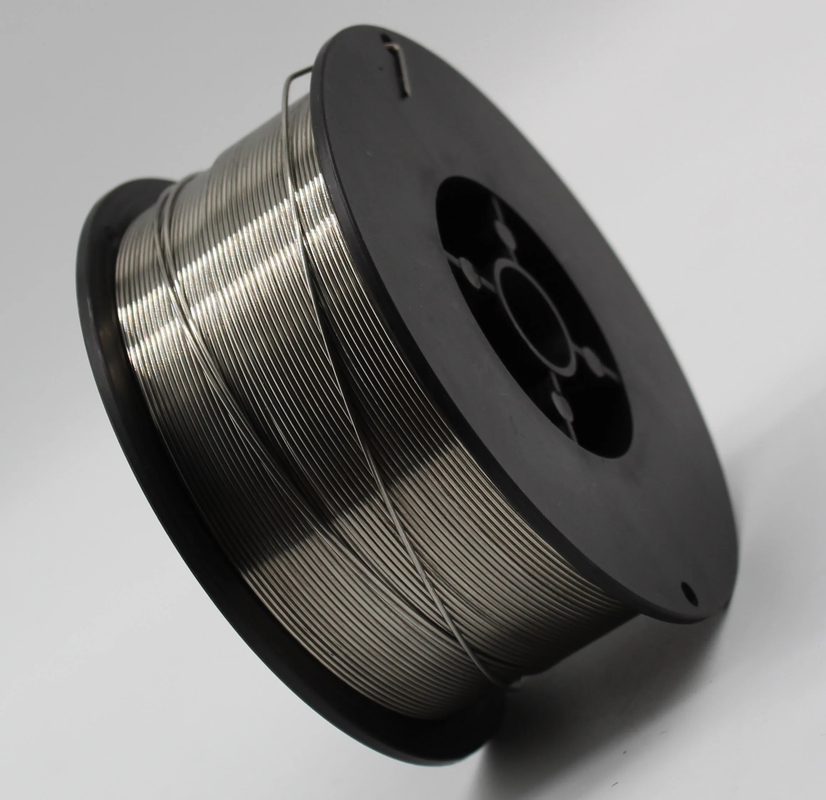

Welding wire is a type of consumable wire that is used in the welding process. It is made from various materials such as stainless steel, mild steel, aluminum, titanium,nickel, alloys and flux-cored wire. The wire is fed through a welding gun and melted to create a bond between two pieces of metal.

Welding wire comes in different sizes and types to suit various welding applications. The wire is selected based on the type of metal being welded, the welding process being used, and the thickness of the metal being welded.

The length of welding wire typically comes in spools or coils and can vary in length depending on the manufacturer and the specific needs of the welder. A common length for welding wire is 200 meters, but it can also be found in longer or shorter lengths.

Overall, welding wire is an essential component in the welding process and plays a crucial role in creating strong and durable welds.

ERNiCrMo-3 N06625 Welding Wire AWS A5.14

ErNiCrMo3 is a type of welding wire that is commonly used for welding nickel-chromium-molybdenum alloys, particularly in applications involving high-temperature and corrosive environments. It is a solid wire electrode with a nominal composition of Ni, Cr, and Mo. ErNiCrMo3 wire is primarily used for joining and overlaying nickel-chromium-molybdenum alloys such as Hastelloy® C-276, Inconel® 625, and similar alloys. These alloys are known for their excellent resistance to corrosion, high-temperature strength, and ability to withstand harsh environments, making them suitable for applications in the chemical processing, petrochemical, and oil and gas industries.

关键词:

隐藏域元素占位

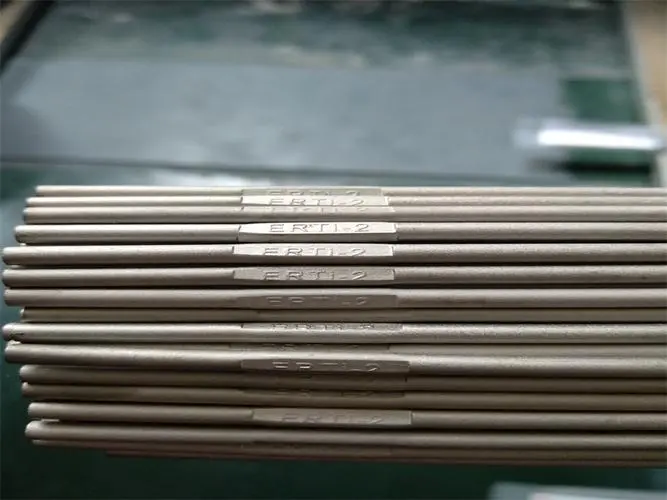

Titanium Welding Wire AWS A5.16

Titanium TIG Wire is a solid titanium wire that offers a balanced combination of mechanical strength and corrosion resistance. It is particularly favored in industries where the ratio of tensile strength to weight is crucial, such as the aerospace sector. This wire is also ideal for applications requiring high-temperature creep resistance. The weld deposit is known for its ductility and exceptional corrosion resistance, especially in highly oxidizing and mildly reducing environments.

关键词:

隐藏域元素占位

Zirconium Straight Welding Wire AWS A5.24

Zirconium Zr 702 is used widely in many industries for process equipment. Major applications include pressure vessels, heat exchangers, piping, tanks, shafts, mixers, and other mechanical equipment; valves; pumps; spargers; trays; and tower packing

关键词:

隐藏域元素占位

Tungsten TIG welding electrode AWS A5.12

TIG welding electrodes are 'non-consumable' as they do not melt in the weld pool, and great care must be taken to avoid letting the electrode come into contact with the weld pool to prevent contamination of the weld. This would be known as tungsten inclusion and can result in weld failure.

关键词:

隐藏域元素占位

Nickel Filler Welding Wire ERNi-1 (FM61)

ERNi-1 (NA61) is used for GMAW, GTAW and ASAW welding of Nickel 200 and 201, joining these alloys to stainless and carbon steels, and other nickel and copper-nickel base metals. Also used for overlaying steel.

关键词:

隐藏域元素占位

ERNiCu-7 N04060 AWS A5.14 Welding Wire

ERNiCu7 Nickel Alloy 60 is used for MIG, TIG, and SAW welding of copper alloys. It is used for joining base materials such as UNS number NO4400, NO4405 and NO5500. This alloy can be used for dissimilar welding applications using various nickel-copper alloys to nickel 200 and to copper-nickel alloys. This can be used for MIG overlay on steel after a first layer with nickel 208.

关键词:

隐藏域元素占位

Inconel 718 Welding Wire AMS 5832

A Nickel-Chromium alloy being precipitation hardenable and having high creep-rupture strength at high temperatures to about 700°C (1290°F). It has higher strength than Inconel X-750 and better mechanical properties at lower temperatures than Nimonic 90 and Inconel X-750.

关键词:

隐藏域元素占位