Contact Info

Add:Tangyan Mansion, No. 58 Keji 1st Road, High tech Zone, Xi'an City, Shaanxi Province

Phone: 0086-29-84504928

E-mail: Tisales@omdtimetal.com

Technological Process

Titanium ore processing: Extracting titanium metal from titanium ore, including crushing, soaking, acidification, and reduction steps, to obtain high-purity titanium metal powder.

Titanium powder smelting: Mix titanium powder with other alloy elements, and then heat it to high temperature (about 1600 ℃) in an electric arc furnace under vacuum until the titanium alloy melts. Afterwards, the melted alloy is rapidly cooled to obtain the required material properties.

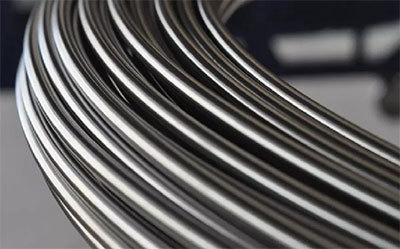

Hot working and cold working: Titanium alloys need to go through two stages: hot working and cold working. Hot processing includes forging and rolling, which can process titanium alloys into shapes such as plates, rods, and tubes. Cold processing includes operations such as stretching, rolling, and bending to further process into parts.

Surface treatment: By sandblasting, acid washing, anodizing and other methods, the surface of titanium alloy can achieve the required roughness, corrosion resistance, surface color and other properties.

Testing and quality control: During the production process, strict quality testing is required for each batch of titanium alloy to ensure that it meets international standards and customer requirements.

Sponge titanium production: The entire process of producing sponge titanium includes mining, beneficiation, enrichment, chlorination, refining, magnesium reduction, vacuum distillation, extraction, crushing, grading, mixing, and sponge titanium products. This process usually starts with smelting titanium chloride slag, then producing titanium tetrachloride, refining titanium tetrachloride, reducing titanium tetrachloride with metallic magnesium, and finally distilling to obtain sponge titanium.

Titanium ingot smelting process: The smelting of titanium and its alloys is divided into two types: vacuum self consumption and vacuum non self consumption smelting. At present, the main method for producing titanium and its alloy ingots is vacuum consumable arc furnace melting (VAR), followed by EB furnace method.