Contact Info

Add:Tangyan Mansion, No. 58 Keji 1st Road, High tech Zone, Xi'an City, Shaanxi Province, P. R. of China.

Phone: 0086-29-84504928

E-mail: Tisales@omdtimetal.com

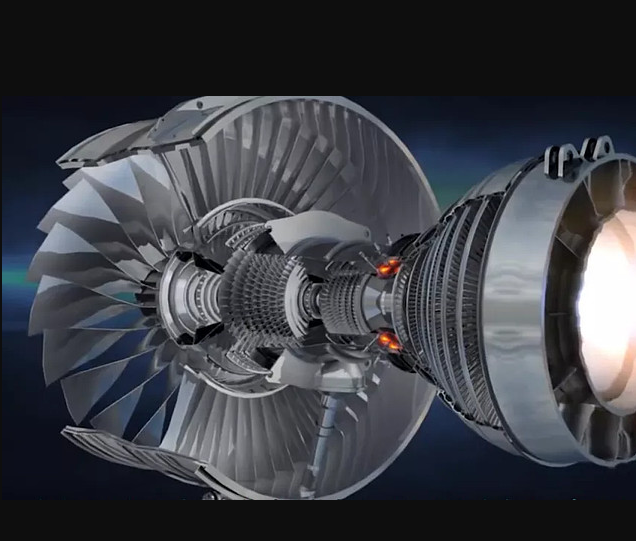

The National Defense and Military Industry Application Conference on Titanium Materials and Technology Equipment will be held in Baoji. Titanium, known as the "strategic metal", is one of the indispensable materials in rockets and missiles today. China is a major producer of titanium materials, but in high-end application fields such as national defense and military industry, core process technology and advanced manufacturing equipment are still important bottlenecks that urgently need to be overcome. In order to assist in the construction of modern military industry and defense equipment system, achieve the goal of advanced development of the titanium industry chain with "independent materials, processes, and equipment", and promote the development of titanium materials and related technology equipment fields, the first National Defense Military Industry Application Conference on Titanium Materials and Technology Equipment will be held in Baoji from May 25th to 27th, 2022

Mar 20,2024

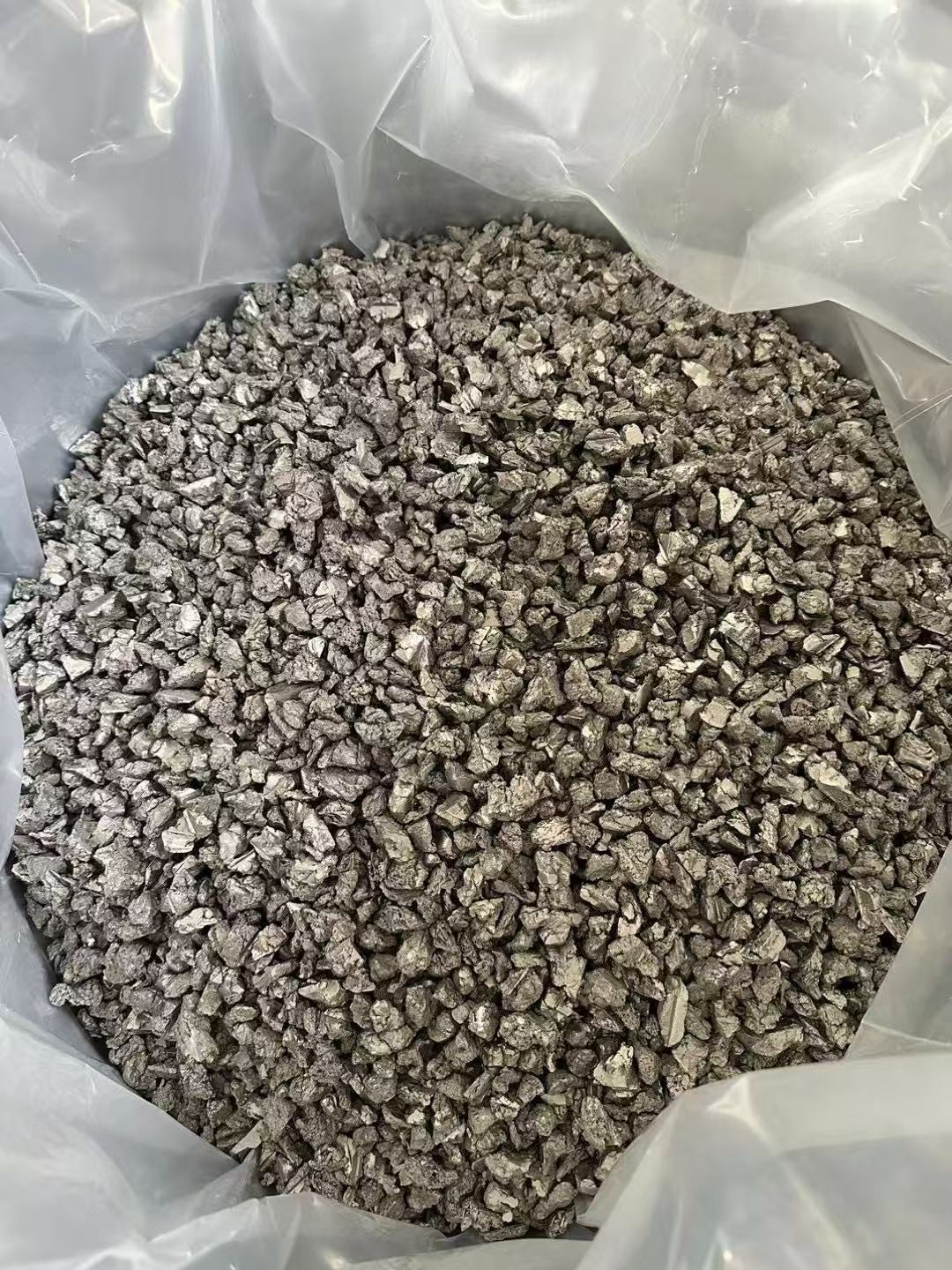

Ilmenite (TiFe03) is smelted in a 6300KVA electric furnace to produce high titanium slag (Ti02), which is then added with coke and chlorine gas in a chlorination furnace to generate crude titanium tetrachloride (TICl4). After being separated by a tray, the copper wire removes vanadium and turns it into fine titanium tetrachloride. It then enters a reduction distillation combined furnace, where magnesium is added to the original material to generate sponge titanium and magnesium chloride. Magnesium chloride is electrolyzed to generate magnesium and chlorine gas for recycling, and the generated sponge titanium is crushed and packaged before leaving the factory

Mar 20,2024

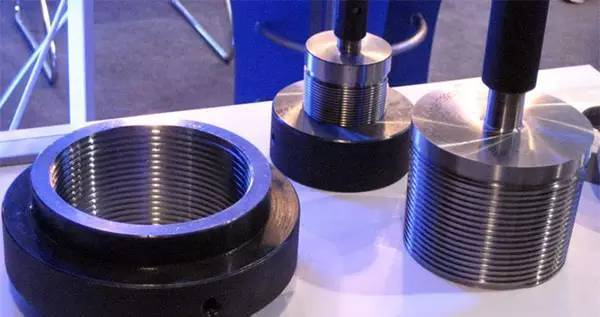

Titanium Alloy Deep Hole Thread Processing Technology

It is quite difficult to process deep hole threads on special material parts. For example, deep hole tapping on a titanium alloy part can be very challenging. If the scraping effect caused by a damaged tap on a nearly completed part results in the part being scrapped, it is very uneconomical. Therefore, to avoid scraping, it is required to use the correct cutting tools and tapping techniques

Mar 20,2024