Contact Info

Add:Tangyan Mansion, No. 58 Keji 1st Road, High tech Zone, Xi'an City, Shaanxi Province

Phone: 0086-29-84504928

E-mail: Tisales@omdtimetal.com

Product Search

Quickly Find The Product You Need

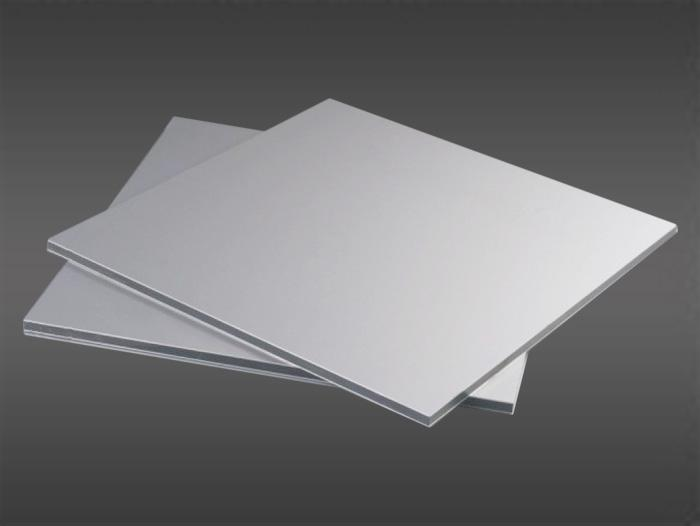

Zirconium Sheet Plate Zr Sheet ASTM B551

- Description

-

Material Grade: Zr 704, Grade R60704— Zirconium-tin alloy; Zr702, Zr705

Standard Specification: ASTM B551

Description: Zirconium features high heat transfer efficiency, low thermal expansion, and high resistance to erosion under tension and localized corrosion. It also has very good resistance in most organic acids, low thermal neutron absorption and corrosion resistance in mineral acids.

Chemical Components(wt%, max):

Grade

Zr + Hf, min

Hafnium

Iron+Chromium

Tin(Sn)

H

N

C

Nb

O

Zr702

99.2

4.5

0.2

....

0.005

0.025

0.05

...

0.16

Zr704

97.5

4.5

0.2~0.4

1.0~2.0

0.005

0.025

0.05

...

0.18

Zr705

95.5

4.5

0.2

....

0.005

0.025

0.05

2.0-3.0

0.18

Mechanical Properties:

Grade

Tensile strength, Mpa, min

Yield strength, MPa min

Elongation in 2 in. or 50 mm, min, % A

Bend Test Radius

Zr702

380

205

16

5T

Zr704

415

240

14

5T

Zr705

550

380

16

3T

Zirconium Sheet Zr Sheet Applications:

1. Aerospace Industry: Used in aircraft structural components, such as wings and fuselage panels, due to its lightweight nature, high strength, and corrosion resistance.

2. Chemical Processing: Employed in equipment and machinery for handling corrosive chemicals and high-temperature environments, including vessels, tanks, and heat exchangers.

3. Medical Implants: Utilized in orthopedic and dental implants due to zirconium's biocompatibility, corrosion resistance, and low allergenic potential, ensuring compatibility with the human body.

4. Nuclear Industry: Applied in nuclear reactor components, such as pressure tubes and fuel cladding, due to zirconium's low neutron absorption cross-section and excellent corrosion resistance in high-radiation environments.

5. Electronics: Utilized in electronic devices for various applications, including as substrates for semiconductor manufacturing and protective coatings for electronic components.

Physical Properties:

Density: 6.5g/cm3; Melting Point: 1852°C; Boiling Point:3580°C

Key words:

Get A Quote