Contact Info

Add:Tangyan Mansion, No. 58 Keji 1st Road, High tech Zone, Xi'an City, Shaanxi Province

Phone: 0086-29-84504928

E-mail: Tisales@omdtimetal.com

Product Search

Quickly Find The Product You Need

Tungsten TIG welding electrode AWS A5.12

- Description

-

Classification Symbol:

Standard Specification:AWS A5.12, ISO 6848

Description:

TIG welding electrodes are 'non-consumable' as they do not melt in the weld pool, and great care must be taken to avoid letting the electrode come into contact with the weld pool to prevent contamination of the weld. This would be referred to as tungsten inclusion and can result in weld failures. The electrodes often contain small amounts of metal oxides that can provide the following benefits:

• Assist in arc starting • Improve the current-carrying capacity of the electrode

• Reduce the risk of weld contamination • Increase electrode life • Enhance arc stability

The oxides used are primarily zirconium, thorium, lanthanum, or cerium.

These are generally added in a 1% - 4% range.

Pure Tungsten (Green) AWS A5.12 EWP, ISO 6848 WP

These TIG electrodes are 'pure' tungsten, non-alloyed with a minimum of 99.5% tungsten and are relatively low cost. They provide good arc stability when using alternating current, whether with balanced or unbalanced waveforms and continuous high-frequency stabilization.

Pure tungsten electrodes are preferred for welding aluminum and magnesium with sinusoidal alternating current because they provide good arc stability with argon and helium shielding gas.

The pure tungsten electrode easily forms a rounded tip but has a tendency to spatter at higher currents, and this must be considered when performing critical welds.

Ceriated 2% (Gray) AWS A5.12 EWCe-2, ISO 6848 WC20These TIG electrodes are alloyed with approximately 2% ceria, a non-radioactive material and the most abundant of the rare earth elements. The addition of this small percentage of cerium oxide enhances the electron emission qualities of the electrode, giving them a better starting characteristic and a higher current-carrying capacity without spatter.

These are general-purpose electrodes that will successfully work with alternating current or direct current negative. Compared to pure tungsten, ceriated tungsten electrodes provide greater arc stability. They have excellent arc starting properties at low current. If used in higher current applications, the cerium oxide may concentrate on the excessively hot tip of the electrode.

This condition and the oxide change will eliminate the benefits of cerium. Non-radioactive cerium oxide has slightly different electrical properties compared to thorium tungsten electrodes. Cerium electrodes work well with advanced square wave power sources and should be sharpened to a modified point.

Thoriated (2% Thorium, Red) AWS A5.12 EWTh-2, ISO 6848 WT20Both 1% and 2% thoriated electrodes are very commonly used as they were the first to show better arc performance compared to pure tungsten for direct current TIG welding.

However, thorium is a low-level radioactive material, so vapors, grinding dust, and thorium disposal raise health, safety, and environmental concerns.

The relatively small amount present has not been found to pose a health hazard. But if welding in confined spaces for extended periods, or if grinding dust from the electrode could be ingested, special precautions regarding adequate ventilation should be taken. The welder should consult informed safety personnel and take appropriate measures to avoid thorium.

The thoriated electrode does not form a ball as pure tungsten, cerium, or lanthanum electrodes do. Instead, it forms several small projections along the face of the electrode when used in alternating current. When used in sinusoidal alternating current machines, the arc moves between the multiple projections and is often undesirable for proper welding. If it is absolutely necessary to weld with this type of machine, higher content lanthanum or thorium electrodes should be used. Thoriated electrodes work well with advanced square wave power sources and should be sharpened to a modified point.

These electrodes are generally preferred for direct current applications. In many direct current applications, the electrode is sharpened to a cone or point. The thorium electrode will maintain the desired shape in those applications where pure tungsten would melt and form the rounded tip. The thorium content in the electrode is responsible for increasing the lifespan of this type compared to pure tungsten.Zirconiated (1% Zirconium, White) AWS A5.12 NONE, ISO 6848 WZ8

This TIG tungsten is alloyed with zirconium oxide (zirconia) and is preferred for alternating current TIG welding when the highest quality work is required and where even the smallest amounts of weld pool contamination cannot be tolerated. This is achieved because zirconium alloyed tungsten produces an extremely stable arc that resists tungsten spatter in the arc.

The current-carrying capacity is equal to or slightly greater than that of a cerium, lanthanum, or thorium alloyed electrode of the same size. Zirconium electrodes are typically used only for alternating current welding with a rounded tip.

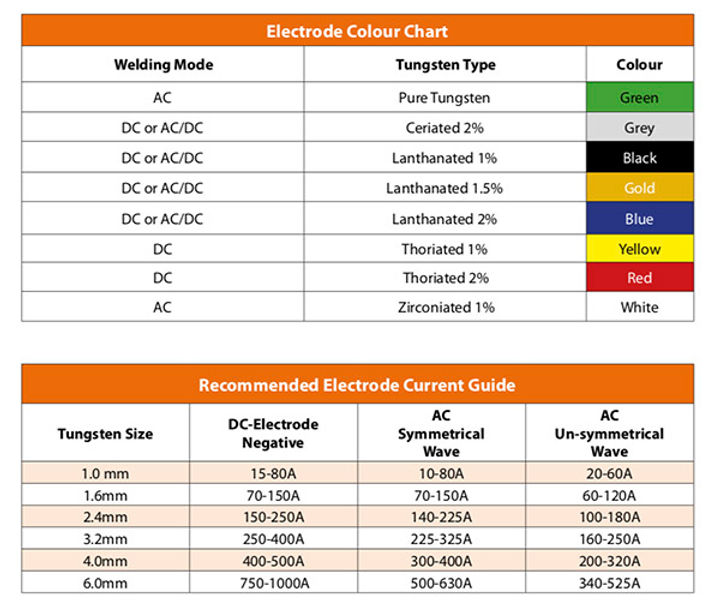

Tungsten electrodes come in a variety of diameters, and the appropriate diameter must be selected for the current to be used and the type for the process mode. To physically identify the type of tungsten, the end is dipped in a color. Care should be taken to sharpen the uncolored end for welding.

Key words:

Get A Quote