Contact Info

Add:Tangyan Mansion, No. 58 Keji 1st Road, High tech Zone, Xi'an City, Shaanxi Province

Phone: 0086-29-84504928

E-mail: Tisales@omdtimetal.com

Product Search

Quickly Find The Product You Need

Titanium Welding Wire AWS A5.16

Moq:

1

Delivery:

- Grade

- ERTi-1

- ERTi-2

- ERTi-3

- ERTi-5

- ERTi-7

- ERTi-9

- ERTi-12

- ERTi-23

-

- Commodity name: Titanium Welding Wire AWS A5.16

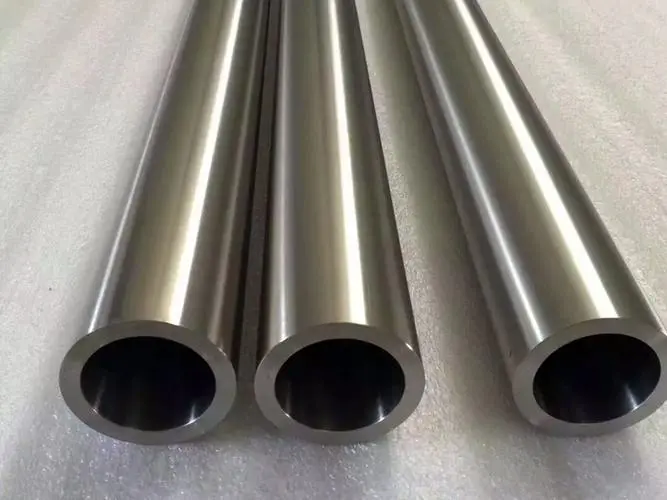

Titanium TIG Wire is a solid titanium wire that offers a balanced combination of mechanical strength and corrosion resistance. It is particularly favored in industries where the ratio of tensile strength to weight is crucial, such as the aerospace sector. This wire is also ideal for applications requiring high-temperature creep resistance. The weld deposit is known for its ductility and exceptional corrosion resistance, especially in highly oxidizing and mildly reducing environments.

Titanium TIG Wire is a solid titanium wire that offers a balanced combination of mechanical strength and corrosion resistance. It is particularly favored in industries where the ratio of tensile strength to weight is crucial, such as the aerospace sector. This wire is also ideal for applications requiring high-temperature creep resistance. The weld deposit is known for its ductility and exceptional corrosion resistance, especially in highly oxidizing and mildly reducing environments.

We can also produce Titanium Welding Wire Drum with 50kg, 100kg.

-

Grade Synonym: Titanium Gr1, ER Ti-1, UNS R50250, Solid Titanium welding wire Grade 1 (purest grade), Titanium TIG Wire. Ti0100

Relevant Standard: AWS A5.16, ASTM F67

Description:

ERTi-1 is commonly referred to as commercially pure (CP) titanium. ERTi-1 is commonly used for welding applications that call for higher temperature resistance and resistance to chemical reagents. This wire is a soft and ductile titanium containing excellent corrosion resistance and impact toughness. This alloy is a prime choice for applications in aerospace, architecture, power generation, medical equipment, hydro-carbon processing, marine components, exhaust pipe components, desalination, chemical processing, and motorsports.

Chemical Components(wt%)

Element

C

O

N

H

Fe

Al

V

Pd

Ni

Mo

Other

Each

Other

Total

Ti

min

--

0.03

--

--

--

--

--

--

--

--

--

--

max

0.03

0.10

0.012

0.005

0.08

--

--

--

--

--

0.1

0.4

Rem.

Application Fields:

ERTi-1. Grade 1 is the lowest strength unalloyed (or Commercially Pure—CP) grade. Grade 1

is used in applications where ductility is paramount, such as explosive cladding, loose linings, expanded metal, and deep drawing applications. It is also used in electrolytic applications like coated anode substrates for production of chlorine and sodium chlorate.

-

Grade Synonym: ERTi-2, TIG Wire, UNS R50400, Ti0120

Relevant Standard: AWS A5.16, ASTM F67

Chemical Components (wt%)Element

C

O

N

H

Fe

Al

V

Pd

Ni

Mo

Other

Each

Other

Total

Ti

min

--

0.08

--

--

--

--

--

--

--

--

--

--

max

0.03

0.16

0.015

0.008

0.12

--

--

--

--

--

0.1

0.4

Rem.

Application Fields:

- Aerospace Industry: Especially where the ratio of tensile strength to weight is crucial.

- Petrochemical Industry: For equipment and components that require corrosion resistance and strength.

- Chemical Process Industries: Suitable for equipment exposed to corrosive chemicals and high temperatures.

- High-Temperature Applications: For components that operate in environments requiring creep resistance.

-

Grade Synonym: ERTi-3, UNS R50550, Ti0125

Relevant Standard: AWS A5.16, AMS 4951

Description:

ERTi-3, Titanium Grade 3 welding alloy in welding wire, rod, and electrode form; available in sizes 0.005″ to bar. ER-Ti-3 is a commercially pure, CP, titanium that is higher strength. Due to its higher strength, it is best when used in instances where higher strength reduces metal thickness is needed. Titanium Grade 3 is ideal for applications in the aerospace, chemical processing, medical, and marine industries where moderate strength and major corrosion resistance are needed.

Chemical Components(wt%)Element

C

O

N

H

Fe

Al

V

Pd

Ni

Mo

Other

Each

Other

Total

Ti

min

--

0.13

--

--

--

--

--

--

--

--

--

--

max

0.03

0.20

0.02

0.008

0.16

--

--

--

--

--

0.1

0.4

Rem.

Application Fields:

ERTi-3, Titanium Grade 3 welding alloy in welding wire, rod, and electrode form; available in sizes 0.005″ to bar. ER-Ti-3 is a commercially pure, CP, titanium that is higher strength. Due to its higher strength, it is best when used in instances where higher strength reduces metal thickness is needed. Titanium Grade 3 is ideal for applications in the aerospace, chemical processing, medical, and marine industries where moderate strength and major corrosion resistance are needed.

-

Grade Alias: ERTi-5, Gr5 Titanium Welding Wire, Ti-6Al-4V Welding Wire, UNS R56400, Ti6402

Relevant Standard: AWS A 5.16, AMS4954, ASTM F67Description:

ERTi-5 commonly called “6-4”is a TIG, MIG, and submerged arc fillermetal use for welding alloyed Titanium with 6% & Aluminum 4%.This grade is commonin the Titanium fillers due to its relatively low cost and good availability. With its high tensile strengths and good weld ability it can be heat treated to exhibits a higher fatigue, toughness found in petro chemical, aircrafts components, turbine parts and blades. Its corrosion resistance is generally compared to Grade 2 but yield a higher strength.

Chemical Components(wt%)Element

C

O

N

H

Fe

Al

V

Pd

Ni

Mo

Other

Each

Other

Total

Ti

min

--

0.12

--

--

--

5.50

3.50

--

--

--

--

--

max

0.05

0.20

0.030

0.015

0.22

6.75

4.50

--

--

--

0.1

0.4

Rem.

Application Fields:

ERTi-5, titanium Grade 5 is also known as TI 6AL-4V. This alloy is a filler metal commonly used to weld alloys of similar composition. ERTi-5 is a high strength alloy with good weldability and is commonly used in the aerospace, medical, marine, and chemical processing industries. process plants, power generation, oil and gas extraction and sports.

-

Grade Alias: ERTi-7, Titanium Grade 7, Ti Gr7,CP Grade 7 Ti-0.15Pd, UNS R52400, Ti2401

Relevant Standard: AWS A5.16 ERTi-7; ASME SFA A5.16 ERTi-7; UNS R52400, W. NR. 3.7235

Description:

ERTi-7, Titanium Grade 7 is similar to Grade 2, with the addition of the element palladium (Pd). The added element of palladium creates a strong corrosion resistance at a low density. ERTi-7 can be used to weld titanium base metals of similar composition such as 2, 16, and 26. This alloy is typically used in applications of valves, heat exchangers, piping and fittings.

Chemical Components(wt%)Application Fields:

Grade 7 has better corrosion resistance than grade 2 due to the addition of 0.12-0.25% palladium, mechanical properties are similar to grade 2. The deposit is ductile and provides excellent corrosion resistance in oxidizing environments. The unique combination of mechanical strength and corrosion resistance makes the alloy a preferred choice in many applications to prevent or solve problems. The wire is cleaned in a very special way to provide a porous and ductile weld deposit. -

Grade Alias: ERTi-9, ERTI-9 (3Al-2.5V), TiAl3V2.5A, UNS R56320, Ti6321

Relevant Standard: AWS A5.16 ERTi-9; ASME SFA A5.16 ERTi-9

Description:

This material is often referred to as “half 6-4” because the major components are roughly half that found in ERTi-5. Primary use, to date, has been in welding hydraulic tubing and fittings for aircraft. Has the ability to maintain strength at elevated temperatures. Titanium is a reactive metal that is sensitive to embrittlement by oxygen, nitrogen and hydrogen at temperatures above 500F. This can be provided by shielding the metal with high purity inert gas or in a chamber. Cleanliness of the joint is a major factorin producing porosity free welds. Protection of the wire at all times is required to assure cleanliness. Can be fusion welded to Zirconium, Tantalum, Nobium and Vanadium. Should not be fusion welded to Copper, Iron, Nickel, and Aluminum, as it will produce extremely brittle welds.

Chemical Components(wt%)Element

C

O

N

H

Fe

Al

V

Pd

Ni

Mo

Other

Each

Other

Total

Ti

min

--

0.06

--

--

--

2.5

2.0

--

--

--

--

--

max

0.03

0.12

0.012

0.005

0.20

3.5

3.0

--

--

--

0.1

0.4

Rem.

Application Fields:

ERTi-9, Titanium Grade 9 is used to weld base metals where a lower tensile is needed and the application requires superior weldability and ductility. ERTi-9 is often used in applications in pressure vessel frames, oil production, aircraft honeycomb foil and sports equipment.

-

Grade Alias: ERTi-12, UNS R53400, 3.7150, Titanium Tig welding wire grade 12, Ti3401

Relevant Standard: AWS A5.16 ERTi-12; ASME SFA A5.16 ERTi-12; UNS R53400

Description:

ERTi-12, Titanium Grade 12 is a higher strength, formable, alloy than titanium grades 1 through 4. ERTi-12 contains molybdenum and nickel which increases the resistance to corrosion with a lower cost than adding palladium. This alloy is typically used in applications of chemical processing, heat exchangers, valves and pumps.Chemical Components(wt%)

Element

C

O

N

H

Fe

Al

V

Pd

Ni

Mo

Other

Each

Other

Total

Ti

min

--

0.08

--

--

--

--

--

--

0.6

0.2

--

--

max

0.03

0.16

0.015

0.008

0.15

--

--

--

0.9

0.4

0.1

0.4

Rem.

Application Fields:

ERTi-12, This alloy finds its applications in chemical industry and offers excellent Weldability. Often recommended for pressure vessels and piping for its superior strength alone.

-

Grade Alias: ERTi-23; 6Al-4V ELI; Titanium Gr23, UNS R56407, Ti6408

Relevant Standard: AWS A5.16; AMS 4956; MSRR9500/78

Description:

ERTi-23, titanium Grade 23 is also known as TI 6AL-4V ELI. This alloy is a filler metal similar to 6Al-4V in chemical composition, except for the extra low interstitial (ELI) gases. With the ELI gases controlled ERTi-23 has an higher increase in fracture toughness. This alloy is commonly used to weld applications of turbine engines, airframes, liquid hydrogen tanks, etc. that require an alloy with higher ductility and fracture toughness.

Chemical Components (wt%)Element

C

O

N

H

Fe

Al

V

Pd

Ni

Mo

Other

Each

Other

Total

Ti

min

--

0.03

--

--

--

5.5

3.5

--

--

--

--

--

max

0.03

0.11

0.012

0.005

0.20

6.5

4.5

--

--

--

0.1

0.4

Rem.

Application Fields:

• Titanium ERTi-23 welding wire is widely used in welding processing in aerospace, shipbuilding, chemical industry, and other fields.

• It is often used for welding titanium alloy components, such as aero-engine parts, hull structures, chemical containers, etc.

• ERTi-23 titanium welding wire is also suitable for welding and manufacturing of medical equipment, bicycle manufacturing, sports equipment, and other fields.

Key words:

Get A Quote