Contact Info

Add:Tangyan Mansion, No. 58 Keji 1st Road, High tech Zone, Xi'an City, Shaanxi Province

Phone: 0086-29-84504928

E-mail: Tisales@omdtimetal.com

Product Search

Quickly Find The Product You Need

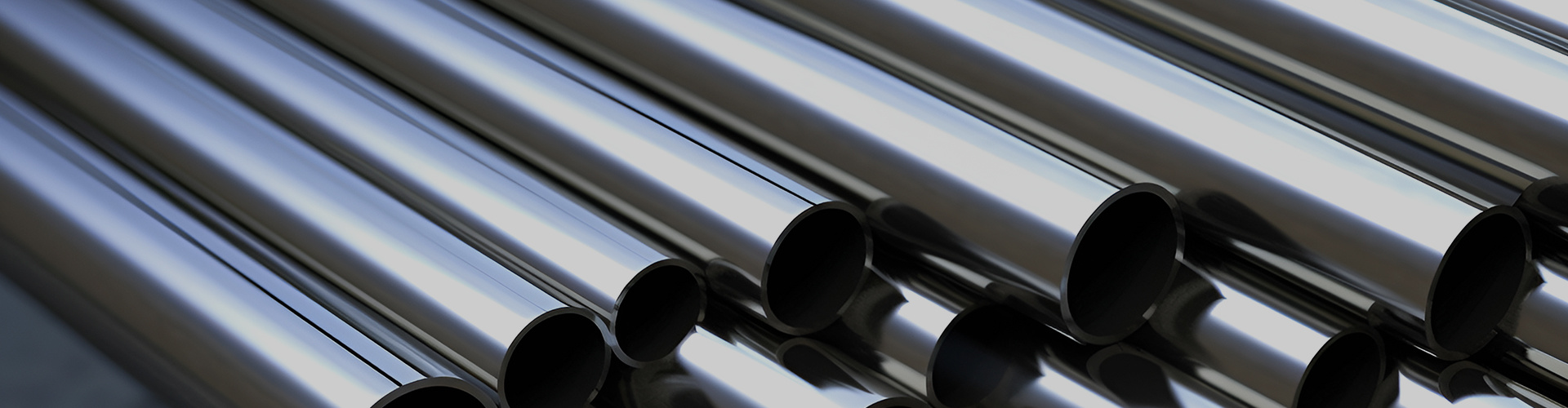

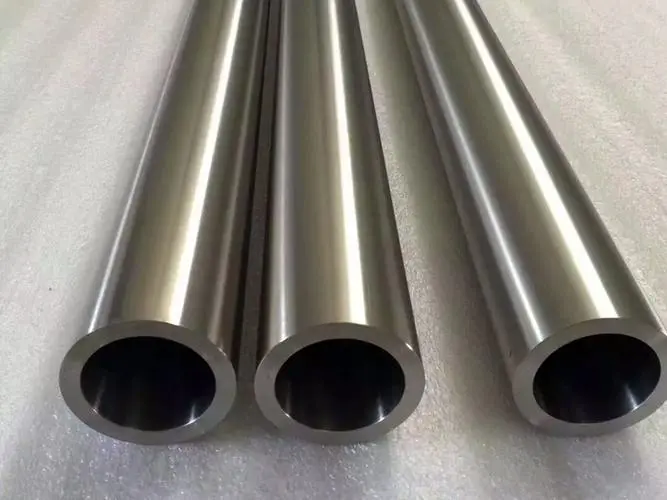

Inconel 600 Tube/Pipe ASTM B167/B163

- Description

-

Material Grade: Inconel 600, UNS N06600 / W.NR. 2.4817, NiCr15Fe

Standard Specification: ASTM B167, ASTM B829, ASTM B517, ASTM B775, ASTM B163, ASTM B516, ASTM B751, AMS 5580,etc.

Inconel 600 Chemcial Composition:

Element

Ni

Cu

Fe

Mn

C

Si

S

Cr

max

72.0

0.5

6.0-10.0

1.0

0.15

0.5

0.0015

14.0-17.0

Inconel 600 Description:

Inconel® 600 is a chromium-nickel alloy designed for use at temperatures up to 2000°F and down to as low as cryogenic levels. The alloy is resistant to reducing environments as well as chloride stress corrosion cracking due to its nickel content and resistant to weaker oxidizing conditions through its chromium content. Inconel 600 is an austenitic alloy with high nickel content that is non-magnetic and has excellent mechanical properties at both high temperatures and cryogenic temperatures.

Inconel 600 Pipes Mechanical Properties:

Density Melting Point Tensile Strength Yield Strength (0.2%Offset) Elongation 8.47 g/cm3 1413 °C (2580 °F) 655 MPa, 95000 psi 310 MPa, 45000 psi 45 % Inconel 600 Tube/Pipe Application:

Alloy 600 is a versatile alloy used in many different applications, including the chemical process industry, aerospace, food processing, electronics, oil and gas, and nuclear power generation. Its elevated temperature oxidation resistance makes it a good choice for heat-treating fixtures, furnaces, incinerators, and other high-temperature equipment.

Key words:

Get A Quote