Contact Info

Add:Tangyan Mansion, No. 58 Keji 1st Road, High tech Zone, Xi'an City, Shaanxi Province

Phone: 0086-29-84504928

E-mail: Tisales@omdtimetal.com

Product Search

Quickly Find The Product You Need

Zirconium Sputtering Target

- Description

-

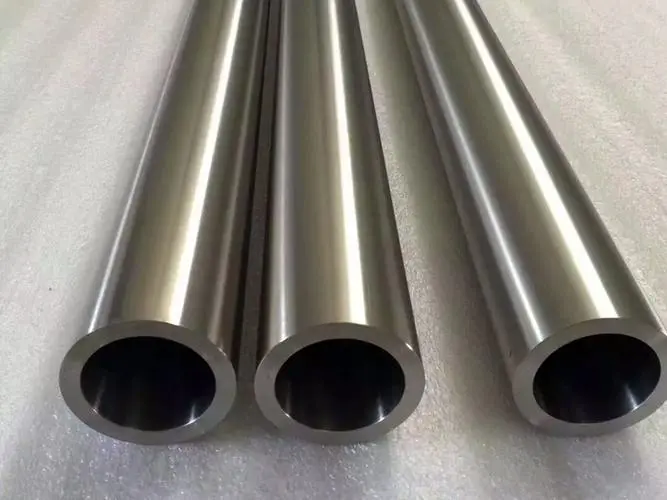

Material : Zrconium Crystal Bar (Raw Materials to make sputtering targets.)

Specification: ASTM B550 Purity: 99.95%

Description: Zr has a tiny neutron absorption cross-section, and a relatively high melting point, making zirconium an excellent material for nuclear power rods. Zirconium sponge and crystal bars are the raw materials to make sputtering targets. Although Zr sponge is cheap and has low purity, it contains a high oxygen content. Zirconium crystal bars have a higher cost and purity, making them ideal materials for sputtering targets.Zirconium features high heat transfer efficiency, low thermal expansion, and high resistance to erosion under tension and localized corrosion. It also has very good resistance in most organic acids, low thermal neutron absorption and corrosion resistance in mineral acids.

Chemical Components(wt%, max):

Grade

Zr + Hf, min

Hf

Fe+Cr

Tin(Sn)

H

N

C

Nb

O

Zr702

99.2

4.5

0.2

....

0.005

0.025

0.05

...

0.16

Zr704

97.5

4.5

0.2~0.4

1.0~2.0

0.005

0.025

0.05

...

0.18

Zr705

95.5

4.5

0.2

....

0.005

0.025

0.05

2.0-3.0

0.18

Zirconium Sputtering Target Applications:

1. Semiconductor Manufacturing: Utilized in the deposition of zirconium thin films onto semiconductor substrates during the fabrication of integrated circuits (ICs), microchips, and other electronic components. Zirconium sputtering targets help create thin films with precise thickness and uniformity, crucial for the performance and reliability of semiconductor devices.

2. Optical Coatings: Used in the production of optical coatings for lenses, mirrors, and other optical components in industries such as telecommunications, aerospace, and scientific research. Zirconium thin films deposited by sputtering targets enhance the optical properties of surfaces, such as reflectivity and light transmission, for various applications.

3. Surface Engineering: Employed in surface modification processes, including the deposition of zirconium coatings for enhancing the wear resistance, corrosion resistance, and biocompatibility of materials. Zirconium sputtering targets enable the deposition of thin films with tailored properties to meet specific requirements in industries such as automotive, medical, and aerospace.

4. Thin Film Solar Cells: Utilized in the production of thin film solar cells, where zirconium-based materials serve as buffer layers, transparent conductive oxides, or back contacts to improve the efficiency and performance of solar panels. Zirconium sputtering targets play a crucial role in depositing these thin film layers with precise control over composition and thickness.

Physical Properties: Density: 6.5g/cm3; Melting Point: 1852°C; Boiling Point:3580°C

Key words:

Get A Quote