Contact Info

Add:Tangyan Mansion, No. 58 Keji 1st Road, High tech Zone, Xi'an City, Shaanxi Province

Phone: 0086-29-84504928

E-mail: Tisales@omdtimetal.com

Product Search

Quickly Find The Product You Need

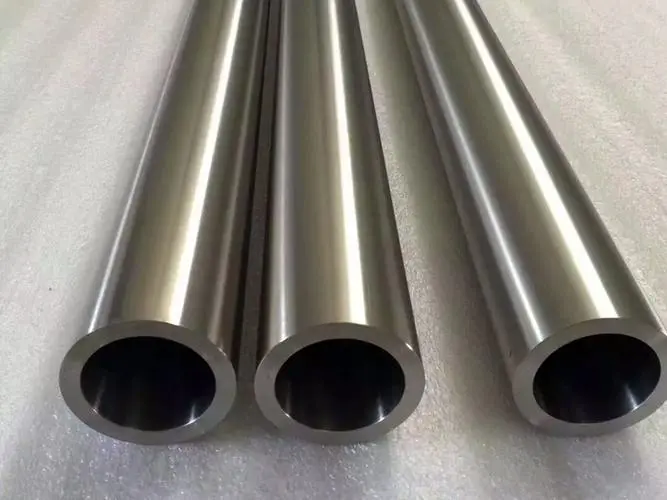

Zirconium Rod/Bar ASTM B550

- Description

-

Material Grade: Zr702, Zr 704, Grade R60704— Zirconium-tin alloy; Zr705

Zr Bar/Rod Standard Specification: ASTM B550

Description: Zirconium features high heat transfer efficiency, low thermal expansion, and high resistance to erosion under tension and localized corrosion. It also has very good resistance in most organic acids, low thermal neutron absorption and corrosion resistance in mineral acids. Zirconium Bars are prized for their exceptional properties, making them indispensable in various industries. Renowned for their remarkable corrosion resistance, zirconium bars remain unaffected by acids, alkalis, and even highly corrosive environments, making them ideal for applications in chemical processing, nuclear reactors, and marine equipment.

Zirconium Bar Size: OD0.5-120*50*2500mm

Chemical Components(wt%, max):

Grade

Zr+Hf, min

Hafnium

Fe+Cr

Tin(Sn)

H

N

C

Nb

O

Zr702

99.2

4.5

0.2

....

0.005

0.025

0.05

...

0.16

Zr704

97.5

4.5

0.2~0.4

1.0~2.0

0.005

0.025

0.05

...

0.18

Zr705

95.5

4.5

0.2

....

0.005

0.025

0.05

2.0-3.0

0.18

Mechanical Properties:

Grade

Tensile strength, Mpa, min

Yield strength, MPa min

Elongation in 2 in. or 50 mm, min, % A

Bend Test Radius

Zr702

380

205

16

5T

Zr704

415

240

14

5T

Zr705

550

380

16

3T

Zirconium Bar Zr Rod Applications:

1. Nuclear Industry: Zirconium Bars are extensively used in nuclear reactors as cladding materials for fuel rods due to their low neutron absorption cross-section. They ensure the integrity of the fuel rods, providing reliable containment for nuclear fuel and preventing radioactive material release.

2. Chemical Processing: Zirconium Bars exhibit outstanding corrosion resistance, making them ideal for use in corrosive chemical environments. They are utilized in chemical processing equipment, such as reactors, vessels, and pipelines, where resistance to acids, alkalis, and other corrosive substances is crucial.

3. Aerospace and Defense: Zirconium Bars are employed in aerospace and defense applications for their high strength-to-weight ratio and resistance to extreme temperatures. They are used in components like aircraft engines, missile casings, and structural parts where durability and performance under demanding conditions are paramount.

4. Medical Devices: Zirconium Bars are utilized in medical implants and devices due to their biocompatibility and resistance to corrosion in bodily fluids. They are used in dental implants, prosthetic limbs, and other surgical instruments where long-term reliability and compatibility with the human body are essential.

5. Marine Equipment: Zirconium Bars are favored for marine applications due to their resistance to corrosion in seawater environments. They are used in shipbuilding, offshore platforms, and desalination plants where exposure to saltwater and harsh marine conditions can cause rapid corrosion in conventional materials.

6. Electronics: Zirconium Bars are employed in certain electronic components and devices due to their excellent electrical conductivity and thermal properties. They are used in applications such as electrodes, sensors, and heating elements where efficient electrical and thermal conductivity is required.

Density: 6.5g/cm3

Melting Point: 1852°C

Boiling Point:3580°C

Key words:

Get A Quote