Contact Info

Add:Tangyan Mansion, No. 58 Keji 1st Road, High tech Zone, Xi'an City, Shaanxi Province

Phone: 0086-29-84504928

E-mail: Tisales@omdtimetal.com

Product Search

Quickly Find The Product You Need

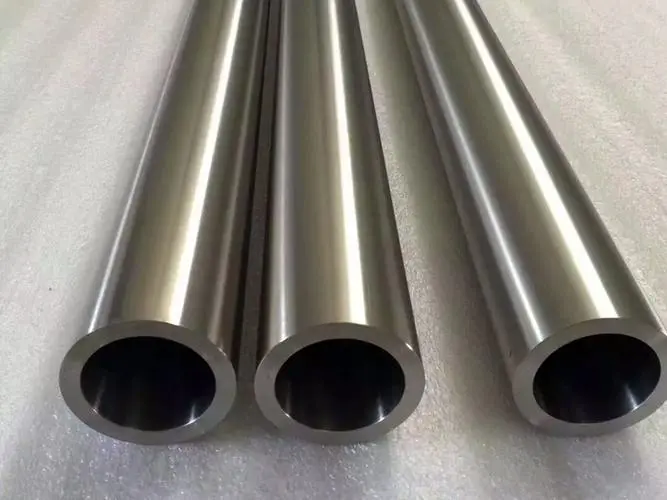

Tantalum Rod Bar ASTM B365 ASTM F560

- Description

-

Material Grade: Pure Ta: R05200; R05400; Tantalum Niobium Rod / Wire R05240 (Ta-40Nb);

Tantalum Tungsten Rod / Wire R05252 (Ta-2.5W), R05255 (Ta-10W).

Tantalum and Tantalum Alloy

R05200, unalloyed tantalum, electron-beam furnace or vacuum-arc melt, or both

R05400, unalloyed tantalum, powder-metallurgy consolidation.

R05255, tantalum alloy, 90 % tantalum, 10 % tungsten, electron-beam furnace of vacuum-arc melt, or both.

R05252, tantalum alloy, 97.5 % tantalum, 2.5 % tungsten, electron-beam furnace or vacuum-arc melt, or both.

R05240, tantalum alloy, 60 % tantalum, 40 % niobium, electron-beam furnace or vacuum-arc melt.Standard Specification: ASTM B365, ASTM F560, AMS 7848(Ta Alloy Bars and Rods 90Ta-10W UNS R05255)

Tatanlum Description:

Tantalum is dark (blue-gray), dense, ductile, very hard, easily fabricated, and highly conductive of heat and electricity. The metal is highly resistant to corrosion by acids: at temperatures below 150 °C tantalum is almost completely immune to attack by the normally aggressive aqua regia.Tantalum Rod & Bar are cold-rolled and annealed in a proprietary process that creates metallurgical properties ideal for such applications as sputtering gun barrels, machining into fasteners, x-ray or radiation shielding, medical markers for surgeons, vacuum furnace heating elements, chlorinator springs, components for light bulbs, or machined parts for chemical processing equipment.

Tantalum Physical Properties:

Density: 16.69 g/cm³

Melting Point:3290 K 3017°C 5463°F

Boiling Point: 5731 K 5458°C 9856°F

Tantalum Rod Bar Application:

1. Electronics industry: Due to its high melting point, low vapor pressure and good electrical properties, tantalum is widely used in the manufacture of electronic equipment such as vacuum tubes, transistors, integrated circuits and electronic connectors.

2. Aerospace industry: Due to its high strength, low density and good high-temperature performance, Tantalum is often used in the aerospace industry to manufacture structural components for aircraft and rockets as well as parts for high-temperature furnaces.

3. Medical field: Due to its biocompatibility and corrosion resistance, Tantalum is widely used in the medical field for the manufacture of medical implants, such as hip and knee implants, dental implants and cardiovascular devices.

4. Chemical and petroleum industry: Tantalum is resistant to corrosion by most acids and alkalis and is therefore used in the manufacture of chemical reaction vessels, pipes, valves and pumps. In the oil industry, Tantalum is also used to manufacture oil drilling equipment and pipework.

5. High-temperature industry: In addition to the above applications, Tantalum is also used in the manufacture of furnace tubes for high-temperature furnaces, crucibles, thermocouple protection tubes and metalworking tools.

Key words:

Get A Quote