Contact Info

Add:Tangyan Mansion, No. 58 Keji 1st Road, High tech Zone, Xi'an City, Shaanxi Province

Phone: 0086-29-84504928

E-mail: Tisales@omdtimetal.com

Product Search

Quickly Find The Product You Need

Tungsten Rod Bar GB/T 4187

- Description

-

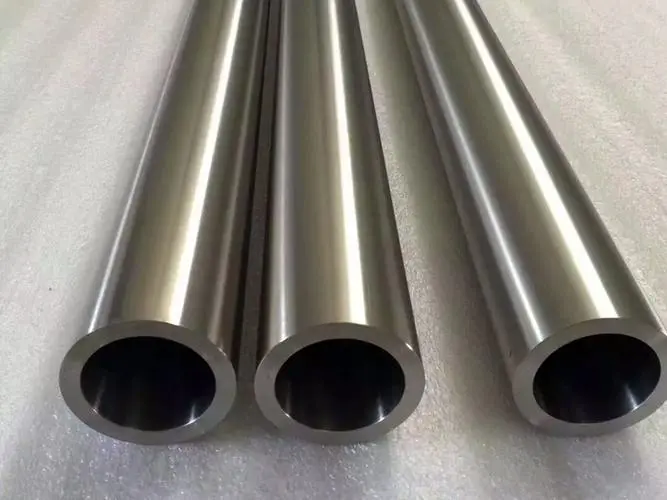

Grade: Pure Tungsten Bar

Standards: ASTM B760, GB/T 4187

Purity: ≥99.95% Density: 18.3 g/cm3 Melting Point: 3410 ℃

Size: Custom dimensions. Diameter: 0.5 - 200 mm. Square shape is also available

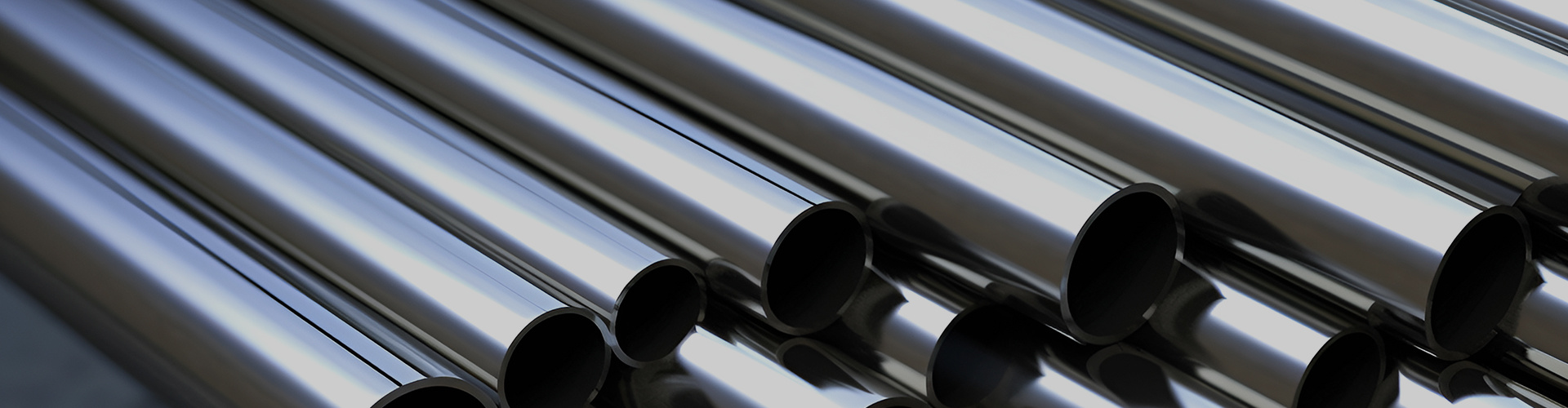

Surface: Sintering surface, forged surface, ground surface, polished surface

Process: Powder MetallurgyProcessing: W powder→Mixing Alloy→Pressing→Sintering→Forming→Heat Treatment→Mechanical Processing→Finished Products by needs.

Characteristics of Tungsten Bars: ∗High Melting Point (3410 ℃)∗Superior Density(ρ=18.3g/cm³)∗Corrosion Resistance∗Excellent Mechaniability,this characteristic allows for the precision machining of intricate components, making tungsten bars valuable in industries that demand high-precision parts, such as the aerospace and medical sectors.

∗Radioactive Shielding Properties: Due to its high density, tungsten is effective in absorbing and attenuating radiation. Tungsten bars find applications in the medical field, particularly in X-ray shielding and radiation therapy, where their density provides efficient protection against ionizing radiation.

∗Versatility in Alloys:Tungsten is often alloyed with other metals to enhance specific properties. Tungsten-Copper (W-Cu) Alloys, for example, Copper is renowned for its excellent thermal conductivity, while tungsten provides high strength. By combining these two elements in an alloy, tungsten-copper achieves a balance of thermal conductivity and mechanical strength.

Tungsten Bar Application:

1. Vacuum Furnace Heating Elements :Tungsten's resistance to high temperatures and its low vapor pressure in a vacuum make pure tungsten rods suitable for use as heating elements in vacuum furnaces. These heating elements maintain their structural integrity under extreme conditions, ensuring reliable performance.

2.Nuclear Industry Components :Tungsten bars are used in various components within the nuclear industry, including radiation shields, reactor control bars, and other critical elements due to tungsten's ability to withstand high radiation levels and extreme conditions.

3. Electron Beam Machining: Tungsten bars are employed as cathodes in electron beam machining processes. The high melting point and electron emission characteristics of tungsten contribute to the precision and efficiency of this machining method.

4. Aerospace Propulsion Systems: In aerospace engineering, tungsten bars are used in components such as rocket nozzles and other propulsion systems. The high melting point and mechanical strength of tungsten make it well-suited for withstanding the extreme conditions associated with space travel.

5. Radiation Shielding:Tungsten bars, due to their high density, are utilized in radiation shielding applications. They are employed in medical facilities for shielding against X-rays and gamma rays, ensuring the safety of personnel and patients.

6. Ion Implantation:In semiconductor manufacturing, tungsten bars are used in ion implantation processes. The ability of tungsten to withstand high-energy ion bombardment makes it suitable for use as a target material in ion implanter.

Key words:

Get A Quote