Contact Info

Add:Tangyan Mansion, No. 58 Keji 1st Road, High tech Zone, Xi'an City, Shaanxi Province

Phone: 0086-29-84504928

E-mail: Tisales@omdtimetal.com

Product Search

Quickly Find The Product You Need

Molybdenum Wire Mo Wire ASTM B387

- Description

-

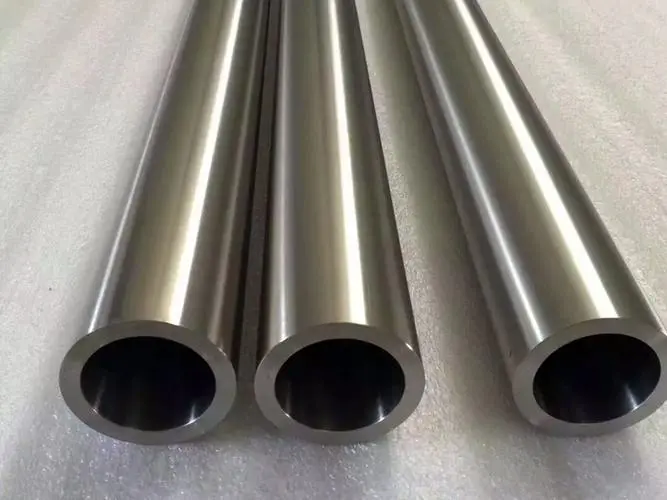

Grade: Molybdenum Bar/Rod 361 grade, Pure Mo 361

Specificatiion: ASTM B387

Material Purity: Mo≥99.95%

Dimensions: Diameter 0.2-4 mm

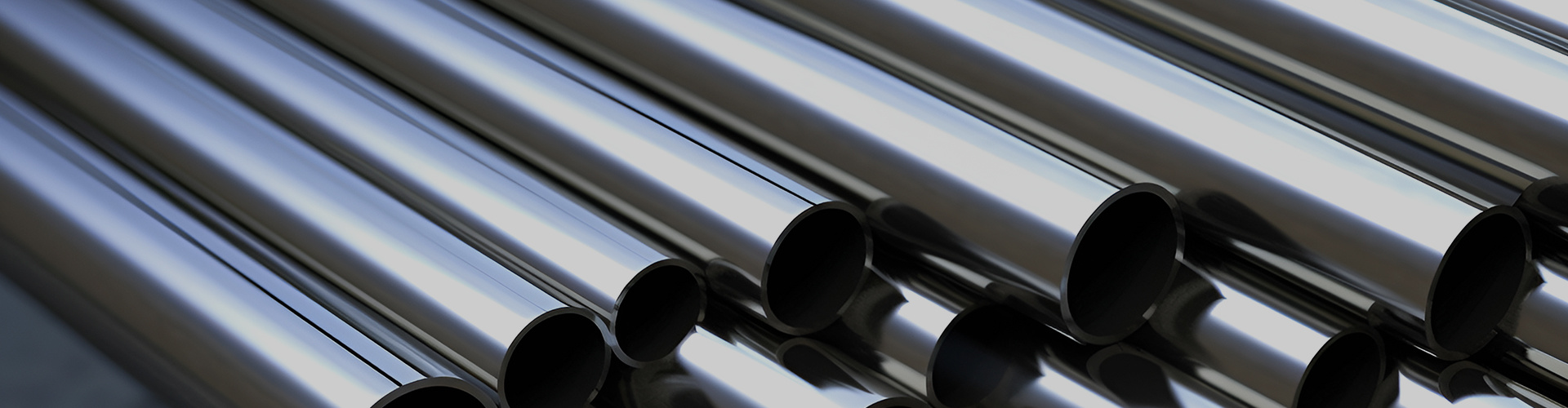

Surface Treatment: Black, Chemically cleanedDescription: The molybdenum wire is produced by stretching high-purity molybdenum rods to various diameters, following pass rolling and rotary forging processes. Our wires offer several advantages, including excellent stability, tensile strength, precision cutting, and low elongation. OMD offers a wide range of molybdenum wire diameters from 0.18mm to 3.0mm, with customizable options available upon request. Molybdenum has high melting point as same as tungsten but is easier to be processed. It is mainly used for high-temperature furnace parts, lighting, and electron tube.

Chemical Components (wt%) Grade 361: Purity 99.95%

Element

C

O

N

Fe

Ni

Si

Mo

max

max

max

max

max

max

max

/

/

0.010

0.0070

0.0020

0.010

0.005

0.010

Balance

Applications:

Molybdenum is an outstanding material that can meet the most exacting requirements of its high melting point, low coefficient of thermal expansion, and high level of thermal conductivity.

Molybdenum wire is used for profile cutting, H2 furnace, heater rod guide rod hook, mandrel, wire, lead, etc. Molybdenum is used in the manufacture of high-temperature-resistant equipment, such as brackets, guide rods, heating rods in the furnace, etc.

Molybdenum wire is mainly used in molybdenum furnaces and electronic tube socket high-temperature hot fields.Physical Properties:

Density: 10.22g/cm3

Melting Point: 2620°C 4748°F

Boiling Point: 4639°C 8382°F

Key words:

Get A Quote