Contact Info

Add:Tangyan Mansion, No. 58 Keji 1st Road, High tech Zone, Xi'an City, Shaanxi Province

Phone: 0086-29-84504928

E-mail: Tisales@omdtimetal.com

Product Search

Quickly Find The Product You Need

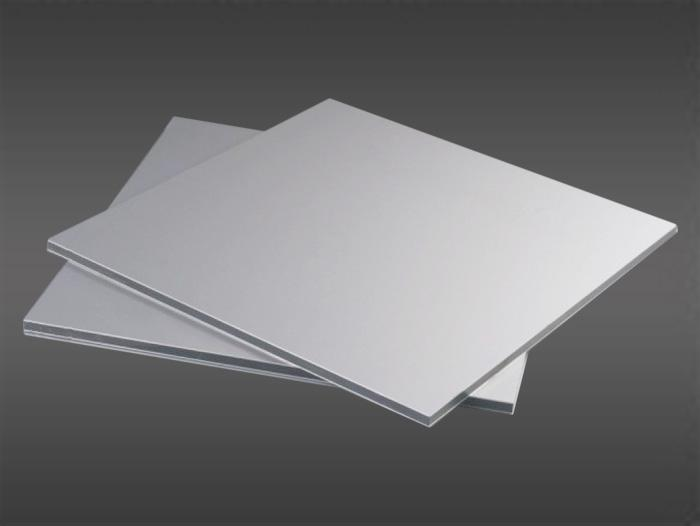

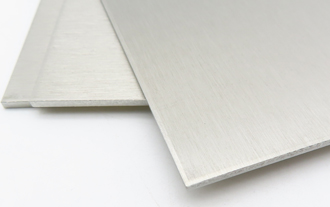

Mo Sheet Pure Molybdenum Sheet Grade 361

- Description

-

Grade: Grade 361, Molybdenum 361

Specification: ASTM B386

Chemical Components (wt%): 361 Grade

Element

C

O

N

Fe

Ni

Si

Mo

max

max

max

max

max

max

max

/

/

0.010

0.0070

0.0020

0.010

0.005

0.010

Balance

Molybdenum Physical & Mechanical Properties:

Molybdenum Physical Properties

Molybdenum Mechanical Properties

Density 0.369 lb/in3

10.3 gm/cm3Tensile Strength

150 (1035) ksi (Mpa)-RT

Melting Point 4760 °F

2625 °C75 (515) ksi (Mpa)-500°C

Thermal Conductivity 0.35 cal/cm2/cm°C/sec 25 (175) ksi (Mpa)-1000°C

Specific Heat 0.061 cal/gm/°C Elongation

Thermal Expansion 4.9 micro-in/°C x 10-6

2.7 micro-in/°F x 10-6Hardness

230 dph

Electrical Resistivity 5.17 microohm-cm Modules of Elasticity

45000 ksi

Description:

Our factory produces all common forms of molybdenum and alloyed products, including plate; sheet; strip; foil; rod; and wire. These are isostatically pressed and sintered from pure metal powders into compact billets through powder metallurgy. Additional deformations and heat treatments are applied, often followed by grinding, polishing, cleaning, or other surface treatments, until the finished product meets exacting, individual customer specifications.

Applications:

Many industries involved with high temperature and electronic products—especially aerospace, electronics, and thermal treatment—rely on molybdenum sheet products in the manufacture of furnace boats, hot zones, thermal barriers, and related applications. That’s because, in addition to its high strength, hardness, and conductivity in high-temperature environments, molybdenum also manifests a low coefficient of expansion and excellent resistance to heat and corrosion.

Physical Properties:

Density: 10.22g/cm3

Melting Point: 2620°C 4748°F

Boiling Point: 4639°C 8382°F

Key words:

Get A Quote