Contact Info

Add:Tangyan Mansion, No. 58 Keji 1st Road, High tech Zone, Xi'an City, Shaanxi Province

Phone: 0086-29-84504928

E-mail: Tisales@omdtimetal.com

Product Search

Quickly Find The Product You Need

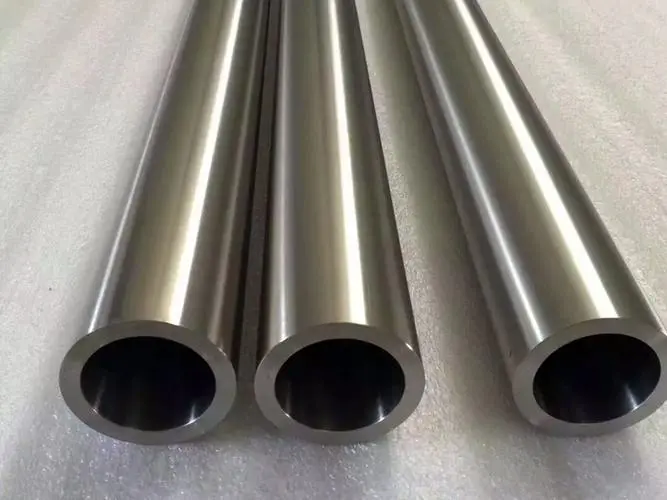

Molybdenum Rod Bar ASTM B387 Mo 360

- Description

-

Grade: Molybdenum Bar/Rod 360 grade, Pure Mo 360

Specificatiion: ASTM B387

Description: The Molybdenum Rod/Bar is made by sintering molybdenum powder and has a high melting point, good thermal conductivity, and low thermal expansion. It is used to produce electric vacuum devices, high-temperature heating elements, etc. Molybdenum bars retain their strength and creep resistance at high temperatures making them an excellent material selection for industrial vacuum furnace heating elements, racks and hardware. The maximum operating temperature of Molybdenum is around 1900°C. At higher temperature it is recommended Tungsten be used. Molybdenum’s outstanding high temperature performance and its ability to withstand aggressive glass melts makes it an applicable material as an electrode in glass melting applications and as a stirrer for molten glass.

Chemical Components (wt%) Grade 360: Purity 99.95%

Element

C

O

N

Fe

Ni

Si

Mo

max

max

max

max

max

max

max

/

/

0.030

0.0020

0.0020

0.010

0.0020

0.010

Balance

Mechanical Properties:

Applications:

In the aerospace and defense industry Molybdenum is often employed in these applications: nose cones, high temperature structural parts, nozzles, leading edges of control surfaces, support vanes, re-entry cones and heat radiation shields.

The electronics market utilizes Molybdenum for cathodes, magnetron end hats, x-ray tube components, filaments and glass-to-metal seals due to good thermal conductivity and low thermal expansion properties. For high-temperature applications Molybdenum is effective in furnace boats, heat shields, windings, structural furnace members and containers for components exposed to high temperatures.

Physical Properties:

Density: 10.22g/cm3

Melting Point: 2620°C 4748°F

Boiling Point: 4639°C 8382°F

Key words:

Get A Quote