Contact Info

Add:Tangyan Mansion, No. 58 Keji 1st Road, High tech Zone, Xi'an City, Shaanxi Province

Phone: 0086-29-84504928

E-mail: Tisales@omdtimetal.com

Product Search

Quickly Find The Product You Need

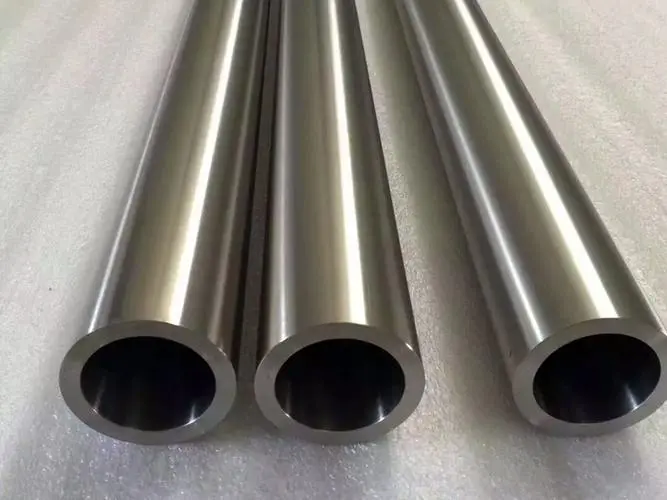

11-Titanium Welding Pipe Transportation Pipe

- Details

- 参数

-

Materials: Titanium

Grade: Gr1, Gr2, Gr3, Gr4 Gr5, Gr7, Gr9, Gr11, Gr12, Gr16,Gr17, Gr23 and etc.

Relevant Standard: ASME B862, DIN17851, TiAl6Zr5Mo1.5, GB/T 26057,GB/T 27684,GB 5031

Chemical Components for frequently used grades:

Gr

C

O

N

H

Fe

Al

V

Pd

Ru

Ni

Mo

Cr

Co

Zr

Nb

Sn

Si

Residuals

/

max

max

max

max

max

min~max

min~max

--

--

--

--

--

--

--

--

--

--

max each

max total

1

0.08

0.18

0.03

0.015

0.20

--

--

--

--

--

--

--

--

--

--

--

--

0.1

0.4

2

0.08

0.25

0.03

0.015

0.30

--

--

--

--

--

--

--

--

--

--

--

--

0.1

0.4

5

0.08

0.20

0.05

0.015

0.10

5.5-6.75

3.5-4.5

--

--

--

--

--

--

--

--

--

--

0.1

0.4

7

0.08

0.25

0.03

0.015

0.30

--

--

0.12-0.25

--

--

--

--

--

--

--

--

--

0.1

0.4

9

0.08

0.15

0.03

0.015

0.25

2.5-3.5

2.0-3.0

--

--

--

--

--

--

--

--

--

--

0.1

0.4

12

0.08

0.25

0.03

0.015

0.30

--

--

--

--

0.6-0.9

0.2-0.4

--

--

--

--

--

--

0.1

0.4

23

0.08

0.13

0.13

0.0125

0.25

5.5-6.5

3.5-4.5

--

--

--

--

--

--

--

--

--

--

0.1

0.4

36

0.04

0.16

0.03

0.015

0.03

--

--

--

--

--

--

--

--

--

42.0-47.0

--

--

0.1

0.4

Partial Wall Thickness ScheduleDN NPS OD /mm Norminal Wall Thickness / mm

Sch5s Schl0S Sch40S Sch80S Sch10 Sch20 Sch300 STD Sch40 Sch60 XS Sch8080 Sch100 Sch120 Sch140 Sch160 XXS 15 1/2 21.3 1,65 2.11 2.77 3.73 — 一 — 2. 77 2.77 — 3.73 3.73 — — — 4.78 7.47 20 3/4 26.7 1.65 2.11 2.87 3.91 — 一 .— 2. 87 2.87 — 3.91 3.91 -—— 一 一 5,56 7.82 25 1 33.4 1.65 2.77 3.38 4. 55 一 一 — 3.38 3. 38 — 4.55 4. 55 -— — — 6.35 9. 09 32 1-1/4 42.2 1.65 2.77 3.56 4,85 — — — 3.56 3. 56 — 4.85 4. 85 — — — 6.35 9.7 40 1-1/2 48.3 1.65 2.77 3.68 5.08 一 — 一 3* 68 3.68 — 5.08 5. 08 -— 一 — 7.14 10.15 50 2 60.3 1.65 2.77 3.91 5.54 — — — 3.91 3.91 — 5.54 5.54 — — —— 8.74 11.07 65 2-1/2 73 2.11 3.05 5.16 7.01 — — — 5.16 5.16 — 7.01 7.01 一 — — 9.53 14.02 80 3 88.9 2.11 3.05 5.49 7.62 -- 一 一 5.49 5.49 — 7.62 7. 62 -— — 一 11.13 15.24 90 3-1/2 101.6 2.11 3.05 5.74 8.08 — — ------ 5.74 5.74 —— 8.08 8.08 一 — 一 一 一 100 4 114.3 2.11 3.05 &02 8. 56 — — — 6.02 6.02 — 8.56 8. 56 — 11.13 — 13.49 17.12 125 5 141.3 2.77 140 6.55 9. 53 — 一 — 6.55 6.55 一 9.53 9.53 — 12.7 — 15.88 19.05 150 6 168.3 2.77 3.4 7.11 10.97 — 一 — 7.11 7.11 — 10.97 10.97 一 14.27 — 18.26 21. 95 200 8 219.1 2.77 3.76 8.18 12, 70 — 6.35 7.04 8.18 8.18 10,31 12,70 12(70 15.09 18.26 20.62 23.01 22. 23 250 30 273 3.4 4.19 9.27 * 32.70 — 6. 35 7.8 9.27 9.27 12.7 12.7 15.09 18.26 21.44 25.4 28.58 25.4 300 12 323.8 3.96 *4.57 *9.53 *12.70 一 6, 35 & 38 9. 53 10.31 14,27 12.7 17.48 21.44 25.4 28.58 33.32 25.4 350 14 355.6 3.96 *4.78 — — 6,35 7.92 9.53 9* 53 I1.13 15.09 12.7 19.05 23.83 27.79 31.75 35.71 一 400 16 406.4 4.19 *4.78 — — 6.35 7.92 9.53 9.53 12.7 16. 66 12.7 21.44 26.19 30.96 36.53 40.49 — 450 18 457 4,19 *4.78 — — 6.35 7,92 11.13 9.53 14.27 19.05 12.7 23.83 29.36 34.93 39.67 45.24 — 500 20 508 4.78 *5.54 一 一 6. 35 9.53 12.7 9.53 15.09 20. 62 12.7 26.19 32.54 38.1 44.45 50.01 — 550 22 559 4.78 *5.54 — — 6. 35 9.53 12.7 9.53 ―- 22.23 12.7 28.58 34.93 41.28 47.63 53.98 — 600 24 610 5.54 6.35 — — 6. 35 9.53 14.27 9.53 17.48 24. 61 12.7 30.96 38,89 46,02 52.37 59.54 — 650 26 660 — — — — 7.92 12. 70 9,53 一 — 12.7 — — — — — — 700 28 711 — — — — 7.92 12. 70 15.88 9.53 — 12.7 — 一 — — •— — 750 30 762 6.35 7.92 — — 7,92 12.7 15.88 9.53 —- — 12.7 一 — — — — — 800 32 813 — — — — 7.92 12. 70 15.88 9.53 17.48 一 12.7 — — — — — 850 34 864 — __ 一 — 7,92 — — 9.53 —- — 12+ 70 — — — — — — 900 36 914 一 — 一 7.92 12. 70 15.88 9.53 19.05 12.7 — — 一 一 950 38 965 — — — — — — — 9.53 —- — 12.7 — — — — — — 1000 40 1 016 — — 一 — — 一 — 9,53 —- 一 12.7 — 一 一 一 — 一 1050 42 1 067 — — 一 — — — — 9.53 —- — 12.7 — — — — — — 1100 44 1 118 — 一 — 一 — — — 9.53 —- — 12.7 — — — — — 一 1150 46 1 168 一 一 — 一 一 9.53 —- — 12.7 — — — — — — 1200 48 1 219 — — — — 9.53 — — 12.7 一 — — 一 — —

Application Fields:Transportation pipe is an essential component in various industries, such as oil and gas, chemical, and aerospace. This type of pipe is commonly used for the transportation of fluids, gases, and other materials from one location to another. The material grade specified in the relevant standards, such as ASTM B861 and ASME B862, ensures the transportation pipe's high quality and reliability.

One of the key factors in the selection of transportation pipe is its chemical composition, as it directly affects the pipe's performance and durability. The TiAl6Zr5Mo1.5 grade, for example, offers excellent corrosion resistance and high strength, making it suitable for applications in harsh environments. Additionally, the mechanical properties of the transportation pipe, such as tensile strength and hardness, play a crucial role in ensuring the pipe's integrity during transportation operations.

In conclusion, transportation pipe plays a significant role in the efficient and safe transport of materials in various industries. By adhering to relevant standards and selecting the appropriate material grade, companies can ensure the reliable performance of their transportation systems. It is essential to consider both the chemical composition and mechanical properties of the transportation pipe to meet the specific requirements of each application field and ensure the overall success of the transportation process.

-

-

Material

- Titanium √

- Nickel √

- PureNickel ×

- Inconel Alloy √

- Hastelloy Alloy √

- Monel Alloy √

- Support Custom √

-

Grade

- Grade 1 Unalloyed titanium, low oxygen √

- Grade 2 Unalloyed titanium, standard oxygen ×

- Grade 2H Unalloyed titanium(Grade 2 with 58ksi minimum UTS)

- Grade 3 Unalloyed titanium, medium oxygen

- Grade 5 Titanium alloy (6 % aluminum, 4 % vana.dium)

- Grade 7 Unalloyed titanium plus 0.12 to 0.25 %palladium, standard oxygen

- Grade 7H Unalloyed titanium plus 0.12 to 0.25 %palladium(Grade 7 with 58 ksi minimum UTS)

- Grade 9 Titanium alloy(3 % aluminum,2.5 % yanadium)

- Grade 11 Unalloyed titanium plus 0.12 to 0.25 %palladium, low oxygen

- Grade 12 Titanium alloy(0.3% molybdenum,0.8 % nickel)

- Grade 13 Titanium alloy (0.5 % nickel, 0.05 % ruthenium),low oxygen

- Grade 14 Titanium alloy(0.5% nickel, 0.05 %ruthenium),standard oxygen

- Grade 15 Titanium alloy(0.5 % nickel, 0.05 %ruthenium),medium oxygen

- Grade 16 Unalloyed titanium plus 0.04 to 0.08 %palladium,standard oxygen

- Grade 16H Unalloyed titanium plus 0.04 to0.08 % palladium(Grade 16 with 58 ksi minimum UTS)

- Grade 17 Unalloyed titanium plus 0.04 to 0.08 %palladium, low oxygen

- Grade 18 Titanium alloy(3% aluminum, 2.5 %vanadium plus 0.04 to 0.08 % palladium)

- Grade 19 Titanium alloy(3% aluminum.8%vanadium,6 % chromium,4 % zirconium, 4 % molybdenum)

- Grade 20 Titanium alloy(3% aluminum,8 %vanadium,6% chromium,4 % zirconium,4 % molybdenum)plus 0.04 to 0.08 % palladium

- Grade 21 Titanium alloy(15 % molybdenum,3 %aluminum,2.7% niobium,0.25 % silicon)

- Grade 23 Titanium alloy(6% aluminum, 4 %vanadium, extra low interstitial. EL)

- Grade 24 Titanium alloy(6% aluminum, 4 %vanadium)plus 0.04 to 0.08 % palladium

- Grade 25 Titanium alloy(6% aluminum. 4%vanadium)plus 0.3 to0.8% nickel and 0.04 to 0.08%palladium

- Grade 26 Unalloyed titanium plus 0.08 to 0.14 %ruthenium

- Grade 26H Unalloyed titanium plus 0.08 to0.14 % ruthenium(Grade 26 with 58 ksi minimum UTS)

- Grade 27 Unalloyed titanium plus 0.08 to 0.14 %ruthenium

- Grade 28 Titanium alloy(3 % aluminum, 2.5 %vanadium plus 0.08 to 0.14 % ruthenium)

- Grade 29 Titanium alloy(6% aluminum, 4%vanadium,extra low interstitial,ELI plus 0.08 to 0.14 %ruthenium)

- Grade 33 Titanium alloy (0.4 % nickel, 0.015 %palladium,0.025 % ruthenium,0.15 % chromium)

- Grade 34 Titanium alloy(0.4 % nickel, 0.015 %palladium,0.025 % ruthenium,0.15 % chromium)

- Grade 35 Titanium alloy(4.5 % aluminum, 2 %molybdenum,1.6% vanadium,0.5 % iron,0.3 % silicon)

- Grade 36 Titanium alloy (45 % niobium)

- Grade 37 Titanium alloy(1.5 % aluminum)

- Grade 38 Titanium alloy(4% aluminum, 2.5 %vanadium.1.5 % iron)

- Grade 39 Titanium alloy(0.25 %iron,0.4 % silicon)

-

Key words:

Get A Quote