Contact Info

Add:Tangyan Mansion, No. 58 Keji 1st Road, High tech Zone, Xi'an City, Shaanxi Province

Phone: 0086-29-84504928

E-mail: Tisales@omdtimetal.com

Product Search

Quickly Find The Product You Need

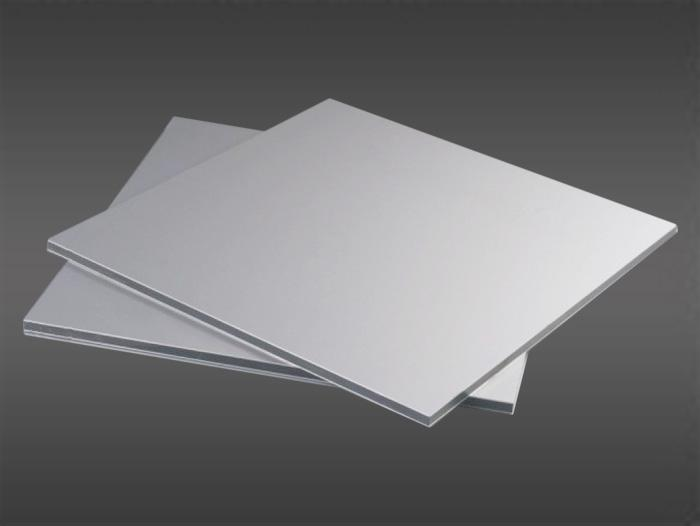

Nickel 201 (Ni201) Coil/Foil ASTM B162

- Description

-

Material Grade: Nickel 201, UNS N02201, Low-Carbon Nickel

Standard Specification: ASTM B162

Coil: Strip, Foil, Ribbon

Description:

Nickel (Ni) metal foil has good corrosion resistance, thermal and electronic conductivity. Nickel metal foil is widely used as a substrate for in-situ growth of other nickel based electrode materials for battery and supercapacitor applications. Nickel foil is a commonly used substrate for graphene fabrication by CVD. Other popular applications can be found in sensors, solar cells and catalysis.

Chemical Components (wt%):

Grade

Ni

Cu

Fe

Mn

C

Si

S

/

min.

max

max

max

max

max

max

Nickel 201Low-C

99.0

0.25

0.40

0.35

0.02

0.35

0.01

Mechanical Properties (Annealed) at room temperature:

Nickel 201, Typical Values at 70°F (21°C), Plate—Hot Rolled, Annealed

/

Yield Strength 0.2% Offset

Ultimate Tensile Strength

Elongation in 2 inches

Hardness

/

ksi

MPa

ksi

MPa

%

Brinell

(3000-kg)Rockwell

BNickel 201

12-35

80-240

50-70

345-485

60-40

--

--

Physical Properties:

Hardness: HV 117 max: gauges ≤ 0.010 inches

Rb 66 max: gauges > 0.010 inchesDensity: 0.322 lbs/in3, 8.90 g/cm3; Melting Range: 2615 - 2535 ° F (1435 - 1445 °C)

Thermal Conductivity, BTU/hr/ft2/ft/°F(W/m•K)

212 °F (100 °C)- 38.8 (67.1)

400 °F (204 °C) - 35.4 (61.3)

600 °F (316 °C)- 36.5 (56.3)Mean Coefficient of Thermal Expansion, in/in/° F (µm/m•K)

80 - 200 °F (27 - 93 °C)- 7.4 x 10-5 (13.3)

80 - 400 °F (27 - 204 °C)- 7.7x 10-5 (13.9)

80 - 600 °F (27 - 316 °C)- 8.0x 10-5 (14.4)Modulus of Elasticity, ksi (MPa)

30.0 X 103 (207 X 103)

Key words:

Get A Quote